New Generation technology and state of the art machinery (Equipments and Gangsaws from Gaspari Menotti, Italy and Line polisher & Bridge cutting machines from Berton, Italy) have been acquired for processing.

Marble manufacturing is the basic building block of any successful Marble export business. And, we have a stronghold in this which makes us one of the top Marble manufacturers in India. Be it granite thickness, edges, surface finish, and others, our advanced granite manufacturing capabilities give a kind of assurance to our buyers that their specific needs will be met perfectly every time.

Performed by qualified and experienced inspectors, we present our global clients with a clear picture of how granite production really looks by being exceptionally transparent.

New Generation technology and state of the art machinery (Equipments and Gangsaws from Gaspari Menotti, Italy and Line polisher & Bridge cutting machines from Berton, Italy) have been acquired for processing.

Multi Block Cutter is a stone cutting machinery manufacturer, mainly producing stone cutting machinery such as bridge cutting machines, CNC bridge saws, marble cutting machines and granite cutting machines.

Automatic polishing machine of newly design, which absorbs the most advanced technology of granite polishing and has created several patent technologies. Automatic marble slab stone polishing Machine.

Single blade block cutter machine cuts the block and convert into slabs max 39". It works very fast and give maximum output at very low cost. It is Automatic Vertical Bock Cutter Machine ( AVBC ).

Calibrating Machines (UCM) are an easy-to-use, cost-effective, hydraulic force calibration system that lasts for generations. Calibration machine is used to calibrate the girdle of a gemstone to a specific size.

Premium quality bridge cutters with out standing performance, It is new generation bridge cutter both for granite and marble cutting. The machine is for slab processing, which adopts PLC Control System.

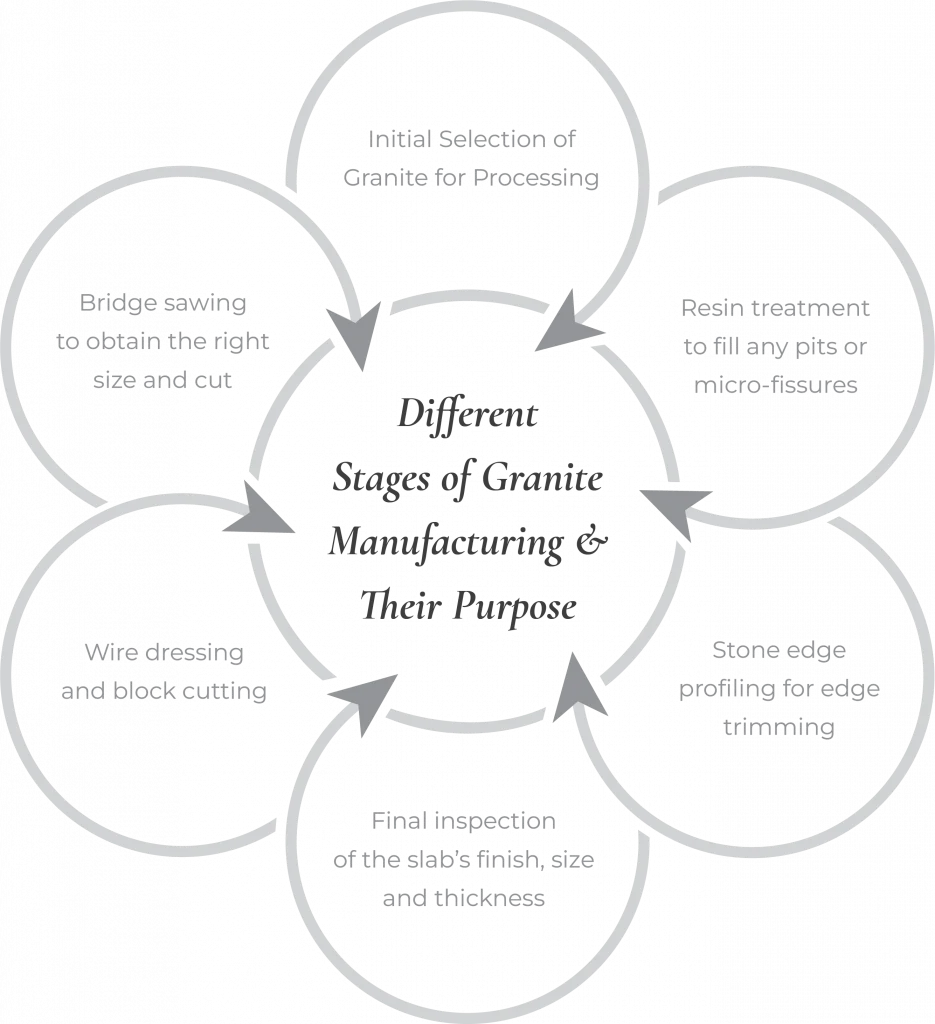

We follow an advanced and comprehensive approach to granite processing. Our 6-step granite manufacturing process guarantees the utmost satisfaction to our clients in terms of granite thickness, size, surface finishes, edges, and colors. From initial granite block selection to giving resin treatment, stone edge profiling, slab inspection, wire dressing & block cutting, and bridge sawing, we strive to process granite in the best possible way to meet the specific needs of granite buyers.

Advanced Machinery for Precise Granite Processing

Spread over a vast area, our both manufacturing units have world-class infrastructure that ensures timely and efficient manufacturing of granite articles. In addition, we have all the latest granite machinery that brings unprecedented levels of perfection in granite manufacturing and processing at all levels.

Simplifying Manufacturing to Enabling Cost-Benefit For Buyers

Not only do we have advanced machinery but we take on a simple but effective approach to granite manufacturing which is another reason why we carry an edge in the domain. Over the years, we have gained immense domain expertise and unmatched exposure to different types of manufacturing approaches. Hence, we take the lead on this.